Demanding applications with high cutting performance and flexibility

The “VMX50Di” 3-axis machining center is designed for demanding applications with high cutting performance and flexibility. Based on our success factors of the smaller 3-axis models, the new development for this takes the “VMX 50i” as its basis. It is designed for machining aluminum as well as for small-part machining and the production of filigree contours on larger parts.

Pliening, Germany, September 2021: The main difference to the established series is, on the one hand, the significantly faster spindle, which is also even more dynamic during startup and braking: It thus provides a power of up to 22 kW and a torque of up to 140 Nm at a maximum speed of 15,000 min-1.

The target group for the VMX 50 Di is contract manufacturers in the single-part and small-batch sectors who typically require higher speeds for their machining operations. Here, the VMX 50 Di is designed for machining aluminum as well as for small-part machining and the production of filigree contours on larger parts. Tools with small diameters can be used particularly efficiently, ideally at high speeds.

Sebastian Herr, Head of Application Technology at HURCO: “Tools with steep taper SK 40 and SK 50 are widely used by our customers. In the contract manufacturing sector, for example, the SK 40 take-up is the benchmark. The VMX 50 Di is perfectly matched to this, as it is equipped with this mount as standard.”

More Information:

https://www.hurco.eu/products/3-axis-machining-centers/

Contact:

Contact:

HURCO Werkzeugmaschinen GmbH

Alexandra Banek

Gewerbestraße 5 a

85652 Pliening

Phone +49 89 905094 29

abanek@hurco.de

Blog post

Greetings to all of our friends engaged in manufacturing with clamping systems,

my name is Sebastian Herr. I am HURCO’s Director of Application Technology.

In the following posting, I will be furnishing you with additional information regarding our “Milling a connecting rod” video.

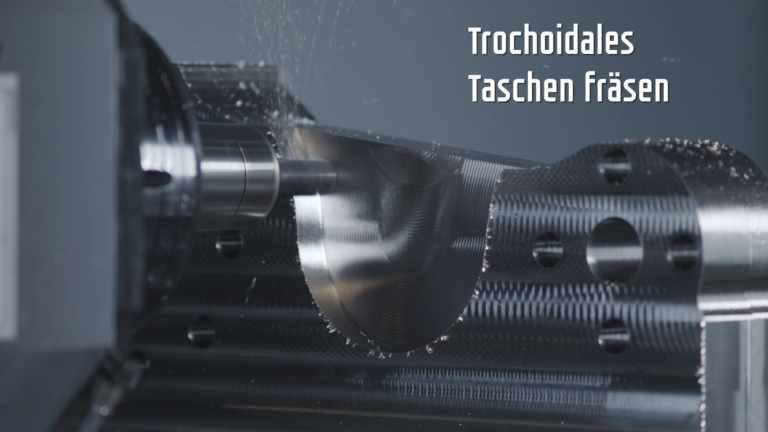

This video shows you the process employed to produce a stainless-steel connecting rod using 5-axis machining. This example clearly demonstrates that processing with trochoidal milling using the HURCO control system is the absolute equal of procedures using the CAM systems as employed by our associated firms. The basic concept remains the same: The tool executes a rotary motion as it proceeds into the workpiece in a penetration process that continues until it is completely immersed and thus able to mill across the entire length of the cutting tool. Throughout the entire processing cycle, the motion pattern is continuously adapted to maintain an invariable and consistent clamping center.

Trochoidal pocket milling

The connecting-rod processing operation that you now have the opportunity to witness is an impressive number. We programmed the pocket milling using TopSolid, which has also been incorporated in our dialog programming. With the HURCO system, the process flows with such seamless smoothness that the simulation displays no detectable difference. The procedures for tool installation and machine set-up also remain absolutely identical, while the program proceeds with no pauses or interruptions of any kind. This unites two technologies in a closely knit combination: HURCO contributes the foundational dialog programming while the CAM builds upon this basis with the DIN-ISO code.

The connecting-rod processing operation that you now have the opportunity to witness is an impressive number. We programmed the pocket milling using TopSolid, which has also been incorporated in our dialog programming. With the HURCO system, the process flows with such seamless smoothness that the simulation displays no detectable difference. The procedures for tool installation and machine set-up also remain absolutely identical, while the program proceeds with no pauses or interruptions of any kind. This unites two technologies in a closely knit combination: HURCO contributes the foundational dialog programming while the CAM builds upon this basis with the DIN-ISO code.

I really want to emphasize that the NC programs are fully integrated in the control system’s programmed conversational operating concept. We didn’t make the decision to apply the CAM system because we had to; we use it because it works! And above all, because it represents the ideal answer to the typical quotidian conditions encountered in contract manufacturing. These environments frequently encompass multiple machines and operators, but just one or two CAM work stations. Under these conditions, a control system offering immense flexibility is an extremely welcome addition. An essential asset is how this system allows programmers to integrate programs stemming from a variety of sources. The only required qualification is a solid background in machining and metal cutting. When we compare the systems, all that the HURCO operator needs is some basic training in the realm of conversational control systems, while the competitors’ systems demand extensive expertise, available only at the cost of considerable time and expenditure.

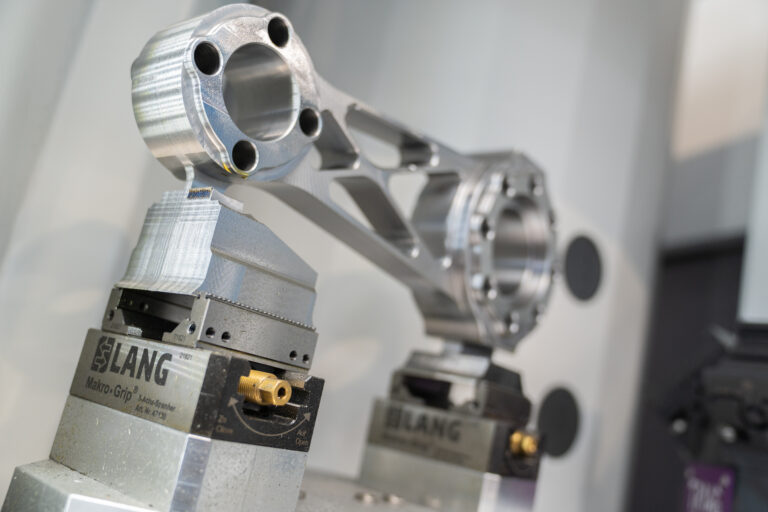

Automated pallet loading

Now I would like to draw your attention to several special features related to the actual machining process. Right at the outset, we focus on the topic of “automation” by showing you the pallet-loading process. In addition to our own in-house products, we also offer solutions for both component and pallet loading contributed by our close associates at ROBOJOB and EROWA. The present scenario focuses on a solution provided by EROWA. At the same time, we remain open to any and all viable automation concepts that might be needed to meet your own specific requirements.

Now I would like to draw your attention to several special features related to the actual machining process. Right at the outset, we focus on the topic of “automation” by showing you the pallet-loading process. In addition to our own in-house products, we also offer solutions for both component and pallet loading contributed by our close associates at ROBOJOB and EROWA. The present scenario focuses on a solution provided by EROWA. At the same time, we remain open to any and all viable automation concepts that might be needed to meet your own specific requirements.

We commence by showing you heavy stainless-steel blocks weighing in at roughly 60 kg, or just over 130 lbs., on two small clamping modules (each 75 mm in width) sourced from LANG TECHNIK. In the interests of achieving secure clamping, the casting has been endowed with an indentation approximately one millimeter in depth and 125 millimeters wide at its lower edge. The casting is processed using a hydraulic mechanism that presses the clamping module’s teeth into the block. The clamping process thus produces a tight positive fit providing immense retaining forces while relying on relatively modest clamping force. This contributes an array of assets of considerable value in the machining and metal-cutting process. It allows the clamping system to serve as a cushioning assembly, resulting in a substantially smoother machining operations. At the end of the day, this means that the connecting rod can be machined at relatively constant load factors combined with a high level of machining performance – in a secured process, despite the high superstructure.

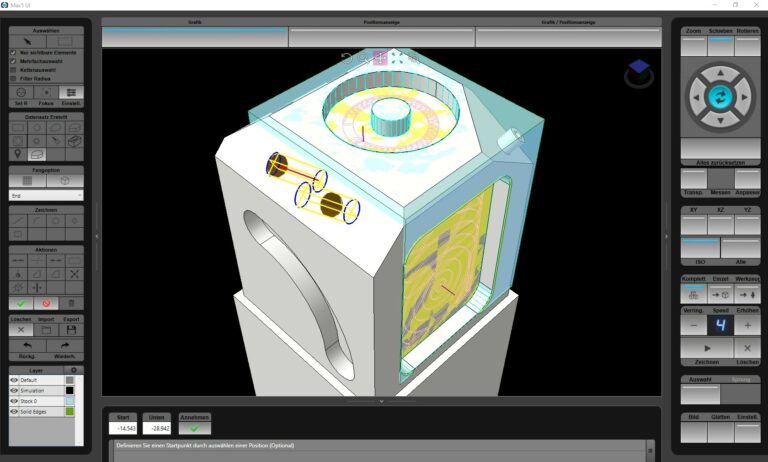

Simulation of unfinished and finished parts

At this juncture, I would like to call particular attention to the simulations of the raw casting and finished part along with the ability to import 3D solid models from the CAD to the control system. This feature is made possible by the “Solid Model Import” option. Starting at second 10, you will be able to see the solid model for the processed part as well as the superimposed casting upon which the machining operation as defined in the control system is simulated. This allows you to check to ensure that everything is proceeding according to plan at this point. From second 39 onward, you receive a clear simulation of the raw casting and machined part, allowing you to monitor the machining path and the rate of metal removal. You can easily view the machine’s current motion patterns along with the depth at which the milling tool is currently operating within the workpiece.

At this juncture, I would like to call particular attention to the simulations of the raw casting and finished part along with the ability to import 3D solid models from the CAD to the control system. This feature is made possible by the “Solid Model Import” option. Starting at second 10, you will be able to see the solid model for the processed part as well as the superimposed casting upon which the machining operation as defined in the control system is simulated. This allows you to check to ensure that everything is proceeding according to plan at this point. From second 39 onward, you receive a clear simulation of the raw casting and machined part, allowing you to monitor the machining path and the rate of metal removal. You can easily view the machine’s current motion patterns along with the depth at which the milling tool is currently operating within the workpiece.

This connecting-rod machining process thus illustrates multiple facets of our approach: The ease with which a DIN/ISO subprogram can be incorporated in the dialog programming as well as the flawless flow of the processing simulation – all in a single cycle. Also apparent is the smooth functionality displayed during execution of potentially difficult metal-cutting operations on stainless steel. The special clamping mechanism ensures minimal vibration. The foundation is furnished by an adaptive milling strategy that can be utilized to full potential thanks to the machine’s vibration-damping properties. In addition, the casting webs to which the connecting rods are attached can be machined so thinly that they can simply be broken off once the machining process has been completed. It is now possible to grind off the burr, at which the connecting rod is finished – in one machining operation and with one clamping process.

Partners

Automation: EROWA

Tool-clamping technology: LANG TECHNIK

CAD/CAM system: TOPSOLID

Distributor: MOLDTECH

Contact:

Contact:

HURCO Werkzeugmaschinen GmbH

Alexandra Banek

Gewerbestraße 5 a

85652 Pliening

Phone +49 89 905094 29

abanek@hurco.de

A project of the heart of Maxime Fontvielle

There is nothing unusual about building a custom bike mainly for a trade show. But what if the trade show in question has nothing to do with custom bikes at all? That is quite surprising.

France, May 2021: The Yamaha SR500 pictured here, a flat tracker or speedway bike with a striking design, is the pet project of 27-year-old Maxime Fontvielle. He works as an applications engineer at the French branch of the U.S. machine tool manufacturer Hurco. He embarked on his career path because of his love of two-wheelers.

“As a teenager,” he tells us, “my passion was motorcycles. While browsing through various forums, I saw people making parts for racing motorcycles of the 90s. That’s when I thought: I want to do that too! I went through apprenticeships at various companies and then started at Hurco.”

By chance, Maxime discovered a scrap Yamaha SR500 for only 100 euros and had a bright idea: he wanted to rebuild it as an exhibit for his company to showcase at machine tool industry trade shows.

The somewhat different exhibit

“At trade shows,” he says, “every year, manufacturers show off their new machines with classic parts from the aerospace industry. In my opinion, it lacked a bit of passion and spirit.”

“At trade shows,” he says, “every year, manufacturers show off their new machines with classic parts from the aerospace industry. In my opinion, it lacked a bit of passion and spirit.”

I wanted to build a beautiful motorcycle with parts that were machined with a machine tool. So I made the suggestion to my boss to get this bike ready as a real speedway monster. American racing discipline, American company … fits like a glove!”

Wisely, Maxime’s boss gave the okay – but there were only three months until the next trade show. So Maxime decided to divide the work. He entrusted the rebuilding of the engine to the Paris workshop Machines et Moteurs, with a very precise checklist. Meanwhile, he concentrated on the chassis.

Back came the engine with a displacement increase to 540 cc and numerous interior changes. Highlights include a sharper camshaft, improved oil flow, a Mikuni TMR36 carburetor and a K&N filter. There’s also a new manifold and a megaphone muffler with countercone, both from SC Project in Italy.

Piece by piece to a unique piece

Maxime’s first task on the chassis was to install a 19-inch rear wheel to match the front wheel. He ended up getting a second SR wheel and machining it to accept a sprocket and 300mm brake disc. He then made special wheel axles, adapted the front wheel to larger bearings, and made both wheels lighter by “splitting” the spokes.

There is no brake at the front, but there is a Brembo caliper and master cylinder at the rear, connected by a stainless steel jacketed line. Since Maxime converted the bike from a rear drum brake, the entire brake system is custom – right down to the caliper mount and foot switches.

Up front is a Yamaha XJR1200 suspension fork; the handlebar stem, triple clamps and handlebar risers are custom.

In the rear, two new shocks are attached to a custom swingarm – a part Maxime’s boss requested to demonstrate the capabilities of Hurco’s machine tools. The swingarm was made in collaboration with CAD/CAM company Mastercam and is custom-made for this bike. It features small details like a brake caliper support bracket and supports for a paddock stand.

In the rear, two new shocks are attached to a custom swingarm – a part Maxime’s boss requested to demonstrate the capabilities of Hurco’s machine tools. The swingarm was made in collaboration with CAD/CAM company Mastercam and is custom-made for this bike. It features small details like a brake caliper support bracket and supports for a paddock stand.

Custom bike in Hurco colors

It’s a nifty piece to admire up close; but that’s just as true of the other custom details on this Yamaha.

From the engine covers to the massive footpegs to the kickstart lever and pedal, Maxime really went all out without overdoing it. An even closer look reveals other fine details, such as the logos engraved on the sides of the triple clamps.

Up top, there’s an Airtech Streamling rear fairing that matches the original gas tank, a front race number plate, and speedway handlebars. For the paint, Maxime’s brother, a designer at Austrian design agency Kiska, helped out with over thirty designs – all in Hurco’s corporate colors.

Everything is now painted in black and gray, with two shades of blue as accents (one for the paint and one for the anodizing). Another friend, Jerome, took care of the decals; they are a thank you to all the partner companies that contributed to the project.

Not only does the SR look damn good, but by all accounts it offers a lot of fun to ride. Soon, Maxime wants to take the bike out for some wild drifts on a speedway track … but until then, his main task is to set the scene for Hurco’s next trade show booth.

Zachary Lovelace

Picture: ©Yann Deret

Article from www.bikeexif.com

Contact:

Contact:

HURCO Werkzeugmaschinen GmbH

Alexandra Banek

Gewerbestraße 5 a

85652 Pliening

Phone +49 89 905094 29

abanek@hurco.de

Higher cutting speed with lower load

Compared to conventional milling methods, trochoidal milling enables higher cutting speeds and deeper cuts while reducing the load on the tool and machine. Supported by the computing power of the modern CNC machining center, this concept enables manufacturers to perform complex milling operations with more speed and less effort. Trochoidal milling is a standard option in Hurco’s WinMax control, with each data set accessible with just one click.

Pliening, Germany, April 2021: In trochoidal or wave milling, the traverse movement of the tool ─ unlike conventional milling ─ is not linear, but runs along a spiral path. The milling tool penetrates the workpiece until it is completely immersed and the cutting process takes place over the entire length of the tool. A special trochoidal milling cutter is used for this purpose, the diameter of which is smaller than the groove or contour to be machined. Through a combination of feed and rotary motion, the grooving angle can be kept constantly below 90 degrees. This reduces stresses on the tool and machine and enables higher milling speeds and shorter machining times.

Tool life extended

“With the trochoidal process, tool life can be extended by up to a factor of ten, and machining times are reduced by 30 to 40 percent,” reports Florian Kerkau, application engineer at Hurco. That’s why trochoidal milling is a standard option in Hurco’s WinMax control, where any data set can be called up with a click. The program sets the grooving point along with all other machining parameters. “Trochoidal milling is always the most economical solution when conventional milling requires multiple depth steps,” explains Kerkau. Trochoidal milling is the process of choice when it comes to milling grooves and slots. Here, the aim is to remove a lot of material in the shortest possible time ─ exactly the right thing for trochoidal milling, which has a clear advantage over conventional milling techniques thanks to its much greater machining depth.

Contact:

Contact:

HURCO Werkzeugmaschinen GmbH

Alexandra Banek

Gewerbestraße 5 a

85652 Pliening

Phone +49 89 905094 29

abanek@hurco.de

Reduce programming time, avoid programming errors

Solid model import option simplifies programming on HURCO machines. Increased profitability through fast programming.

Pliening, Germany, March 2018: Solid model import option simplifies programming for HURCO machines. Programming on 5-axis machines from HURCO can be performed easily and quickly. New and less specially-trained employees can be trained in a short period of time. The new “solid model import” option further reduces the steps. Machine tool manufacturer HURCO has enabled connection of its machines to a solid model import.

Pliening, Germany, March 2018: Solid model import option simplifies programming for HURCO machines. Programming on 5-axis machines from HURCO can be performed easily and quickly. New and less specially-trained employees can be trained in a short period of time. The new “solid model import” option further reduces the steps. Machine tool manufacturer HURCO has enabled connection of its machines to a solid model import.

The programming time is reduced and simplified through simple data importing in the STEP 3D model format. The import option interprets the data and makes production programming directly at the machine possible. The path from workpiece to component becomes more secure as well. The potential for error during programming is reduced many times over, partly because the machining simulation of the written program is shown together with the solid model in a single view. Thus, users can immediately see if the programming matches the finished component and can refinish this component if necessary.

The programming time is reduced and simplified through simple data importing in the STEP 3D model format. The import option interprets the data and makes production programming directly at the machine possible. The path from workpiece to component becomes more secure as well. The potential for error during programming is reduced many times over, partly because the machining simulation of the written program is shown together with the solid model in a single view. Thus, users can immediately see if the programming matches the finished component and can refinish this component if necessary.

Increased profitability through fast programming

HURCO machines are equipped with the intuitively operable “Max5” conversational control system. “Our control system is an absolute highlight and unique feature of ours”, Michael Auer, Managing Director of HURCO GmbH, emphasizes. “It is the fastest in the industry and vastly increases the machine’s efficiency.” DXF files can be directly imported into the CNC control system. Drawings or sketches are imported quickly into a finished program, which contributes to increased profitability in prototype, single piece and small series production.

HURCO machines are equipped with the intuitively operable “Max5” conversational control system. “Our control system is an absolute highlight and unique feature of ours”, Michael Auer, Managing Director of HURCO GmbH, emphasizes. “It is the fastest in the industry and vastly increases the machine’s efficiency.” DXF files can be directly imported into the CNC control system. Drawings or sketches are imported quickly into a finished program, which contributes to increased profitability in prototype, single piece and small series production.

Contact:

HURCO Werkzeugmaschinen GmbH

HURCO Werkzeugmaschinen GmbH

Alexandra Banek

Gewerbestraße 5 a

85652 Pliening

Phone +49 89 905094 29

abanek@hurco.de