- Products

- Control

- News & Media

- Company

- Kontakt

- Produktselektor

Automation with HURCO - More efficiency in production

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationOpen source interface - our basis for your individual automation solution

Automation makes life easier - this also applies to CNC machining and the metal and plastics processing industry. To maximize the efficiency of your production and get the most out of your CNC machines, we support you in automating your HURCO machine - for even faster performance, satisfied customers and higher sales.

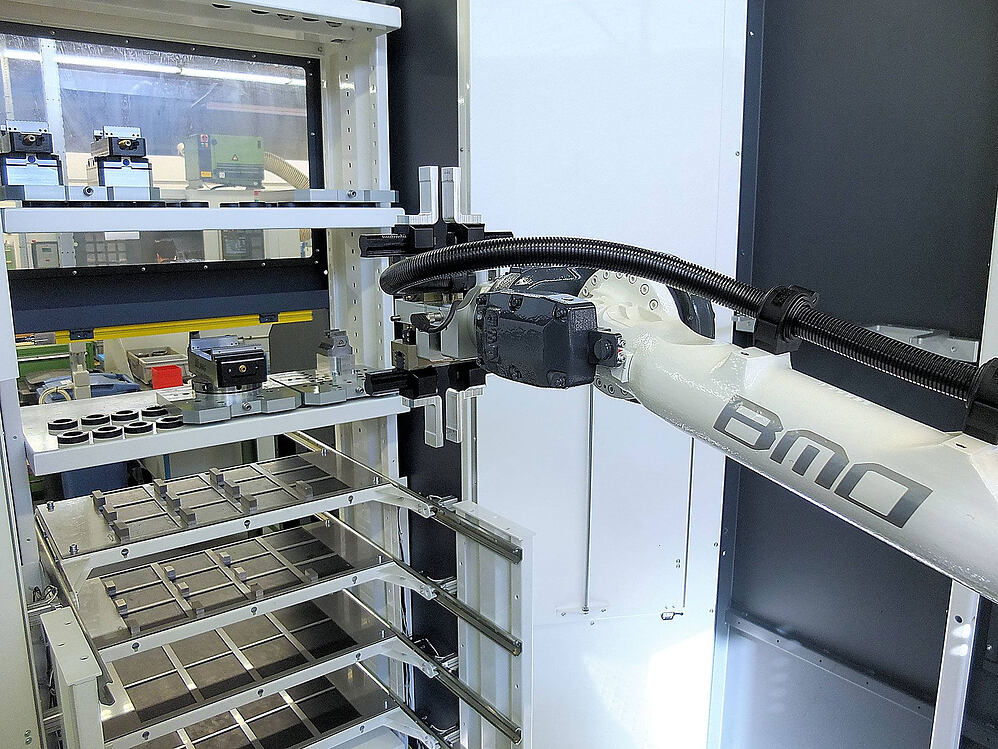

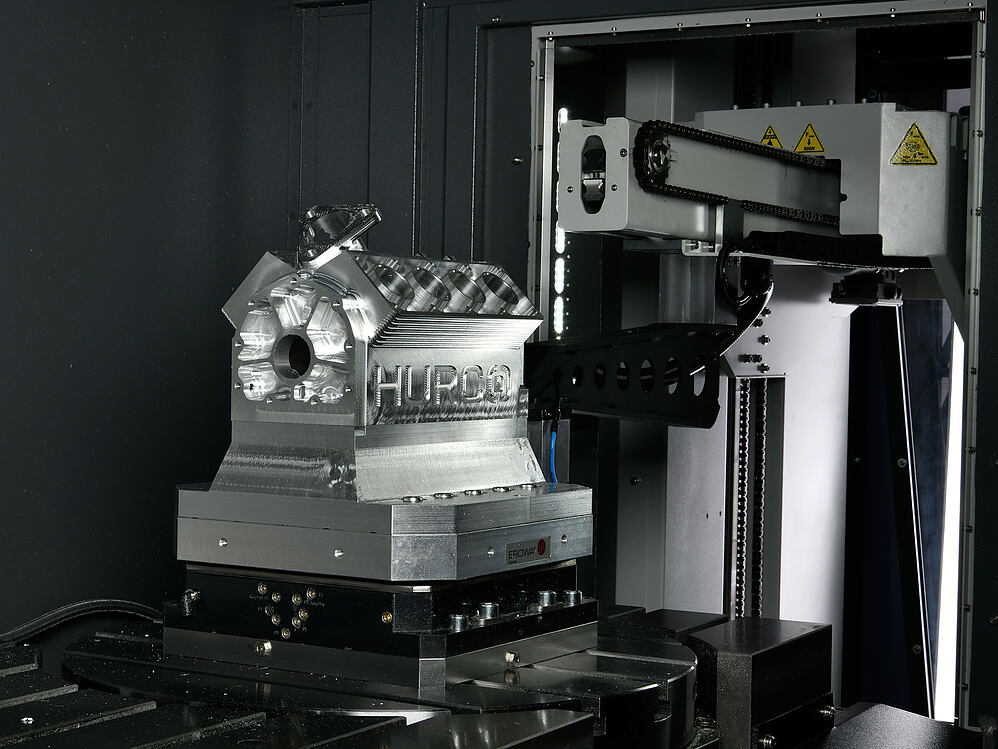

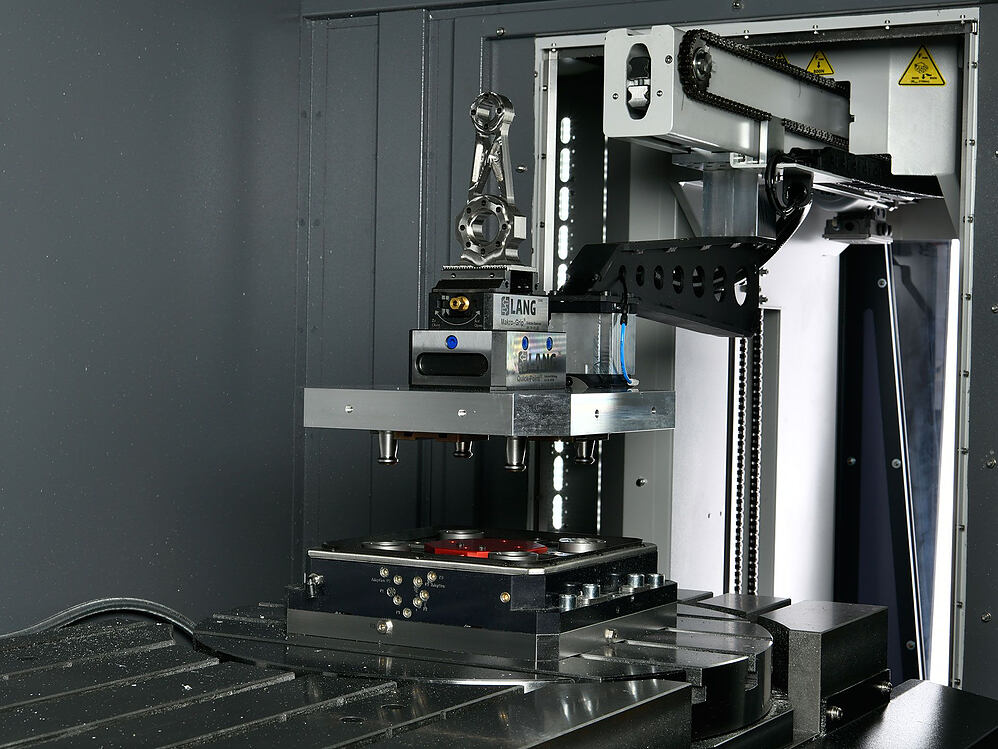

HURCO machines can be connected to almost all robotics and automation solutions for CNC machine tools via an open source interface. We advise you on the way to individual automation and work closely with renowned suppliers to combine all the advantages of automation in a customized implementation for your production: AMF, BMO, Erowa, , FMB, Indunorm, Kösters Maschinenbau, Lang Technik, Pro Cobots, Robojob, Universal Robots, Zero Clamp and many more.

With our team of application engineering employees, experienced machining specialists are available to advise you on the introduction of CNC automation and support you in the digitalization of your manufacturing processes.

Higher CNC capacities through the integration of robotic loading systems

Loading robots are the ideal complement to human resources in your company. The automated feeding and removal of workpieces enables operatorless and fast production of a third shift or even parallel production with several machines under the supervision of a single operator. With a robotics solution, you can achieve higher runtimes for your machines, add flexibility to the processes and production flows in your plant, and make your personnel deployment more efficient. Through the DNC interface, HURCO machining centers and automation systems connect to form a synchronized production unit with higher-level process management. Many loading robots also flexibly change clamping devices and grippers in the course of a production process.

Industrial automation from HURCO

Fit for digital industry 4.0 with HURCO

With our in-house developed WinMax control system, a universal Windows-based operating system and an internationally adapted interface standard, we at HURCO optimally prepare you for the requirements of working in modern industries. For the intelligent networking of machines in production or blockchain solutions between production systems - for example, contract manufacturers and commissioning OEMs - we provide our customers with all the necessary technologies. Our application engineers support you directly on site with the integration and implementation of measures to automate your machines and digitalize processes.

HURCO's CNC machines work with the MT-Connect manufacturing standard. This tool for machine data acquisition allows immediate retrieval of availability and performance analyses as well as visualizations and evaluations for numerically controlled machine tools. This software standard harmonizes perfectly with the Windows-based operating system and the intuitive WinMax control system. The application connects plants, applications and entire factories with each other and offers an integrated total manufacturing system that allows you to holistically increase the productivity of your CNC production.

Using the HURCO Job List, you can quickly and easily create a machining list for complex manufacturing jobs. Programs and subroutines are listed and linked to the corresponding pallet and part number. Your advantage: Additional programming effort is avoided.

This is what the practice of automation looks like

BMO's Titanium robot operates two CNC machines docked to the right and left of the loading system. The parts to be processed are provided on trays in the robot cell. The robotic arm integrated into the cell positions each of them individually in the HURCO CNC machine and removes them after completion to place them back in trays in the cell.

In this way, the EROWA Robot Compact automates 80 pallets: The software of the loading robot takes over and processes the production orders on the processing portal. But it also works the other way around: In this case, the external loading systems are directed via the WinMax control system. Both run via a DNC interface. The EROWA Robot Compact 80 can operate up to two CNC machining centers that are docked to the right and left of the loading system.