- Products

- Control

- News & Media

- Company

- Kontakt

- Produktselektor

News

01.01.2025

New Leadership Duo at HURCO: Shaping the Future Together

04.03.2024

Special sale VMX 42i

16.10.2023

Temporary closure spare parts store

15.09.2023

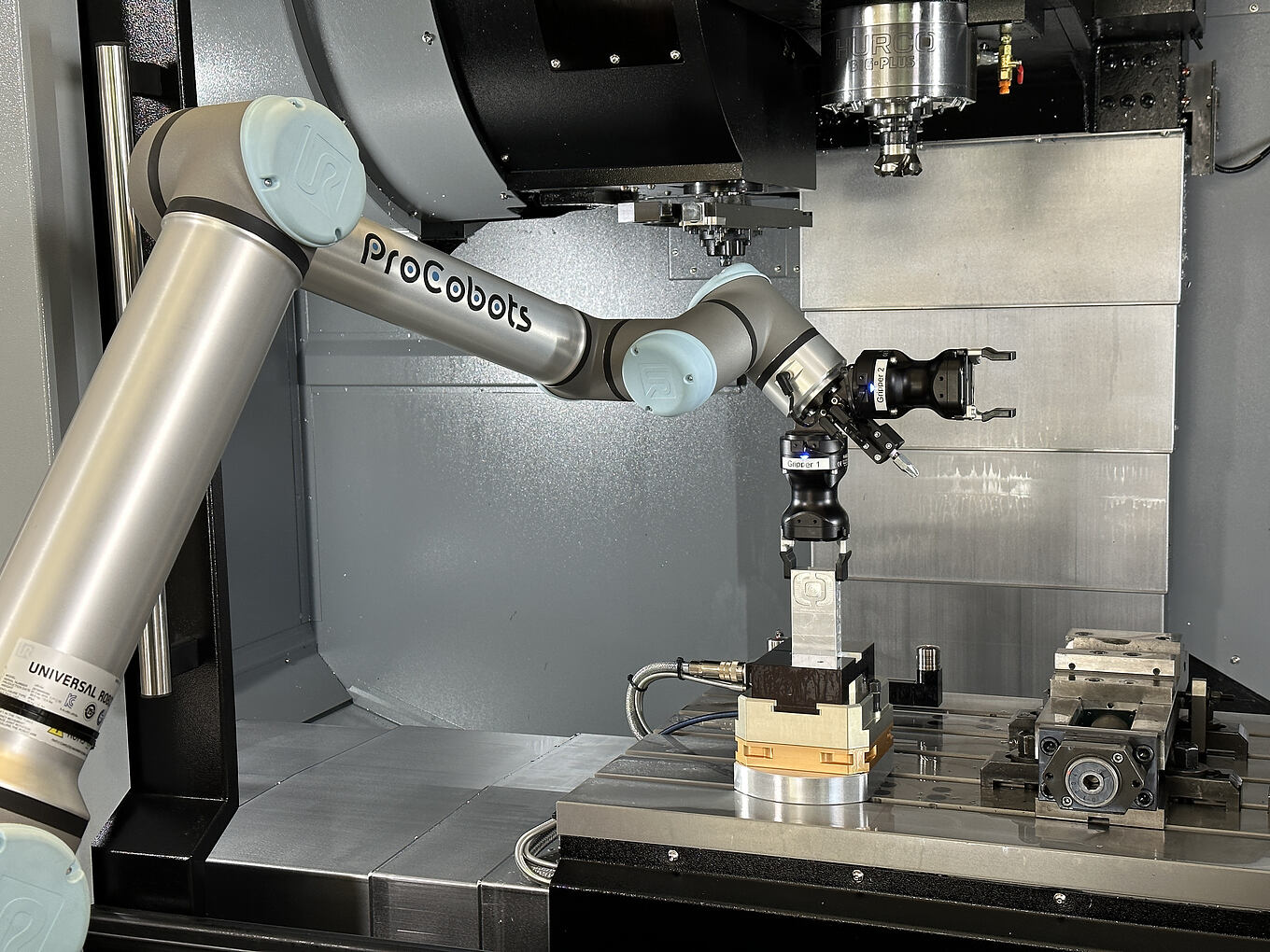

Reinforcement for the team: Cobots make machine loading easy

04.09.2023

Special offer VM 10 i Plus

25.07.2023

EMO 2023: HURCO focuses on automation and simple programming

31.05.2022

HURCO at METAV 2022:

18.02.2022

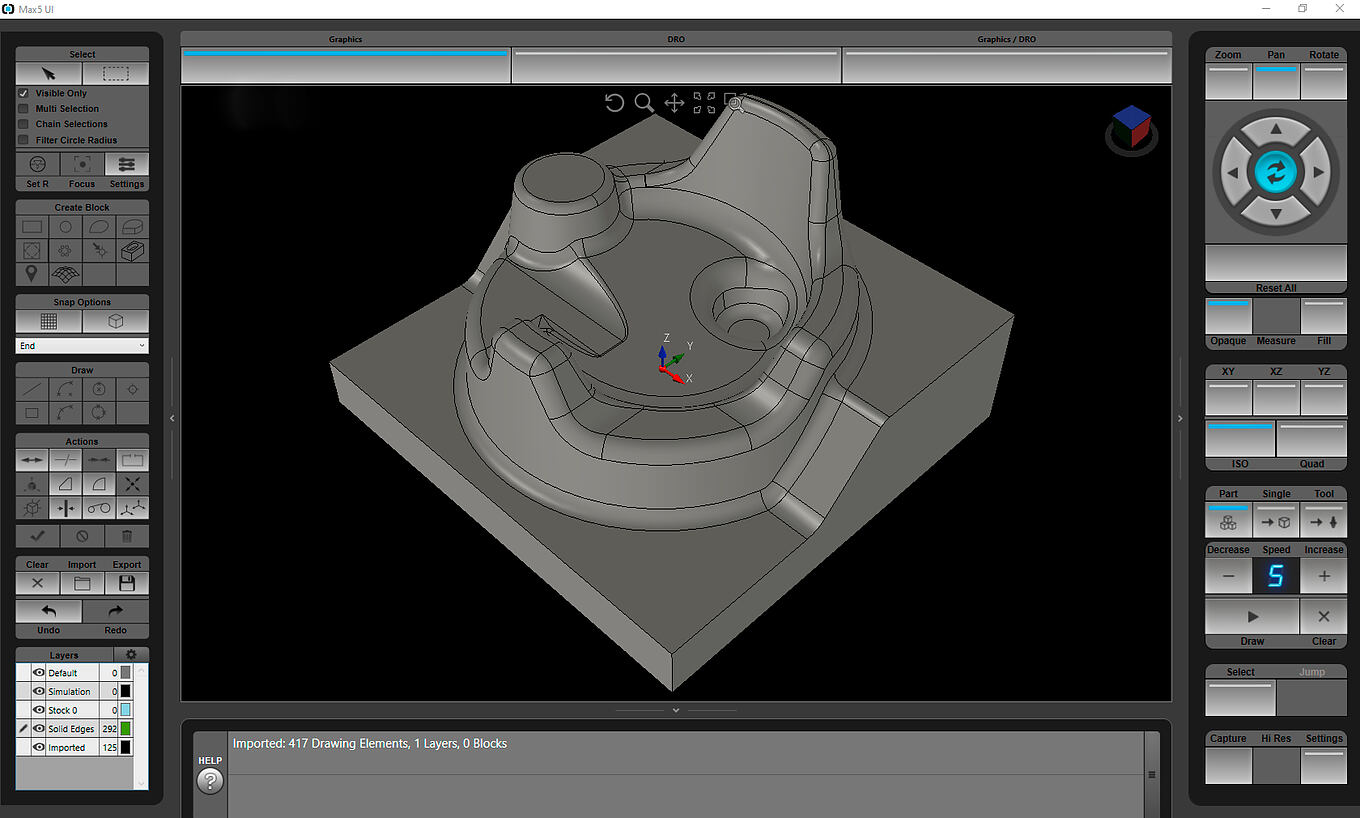

Programming free-form surfaces right at the machine

06.12.2021

Integrated software with smoother running

11.10.2021

New 5-axis-machining center – VCX600i XP

05.10.2021

10,000 HURCO machines have already been installed in Germany

05.08.2021

Demand served with pinpoint accuracy – VMX50Di

02.07.2021

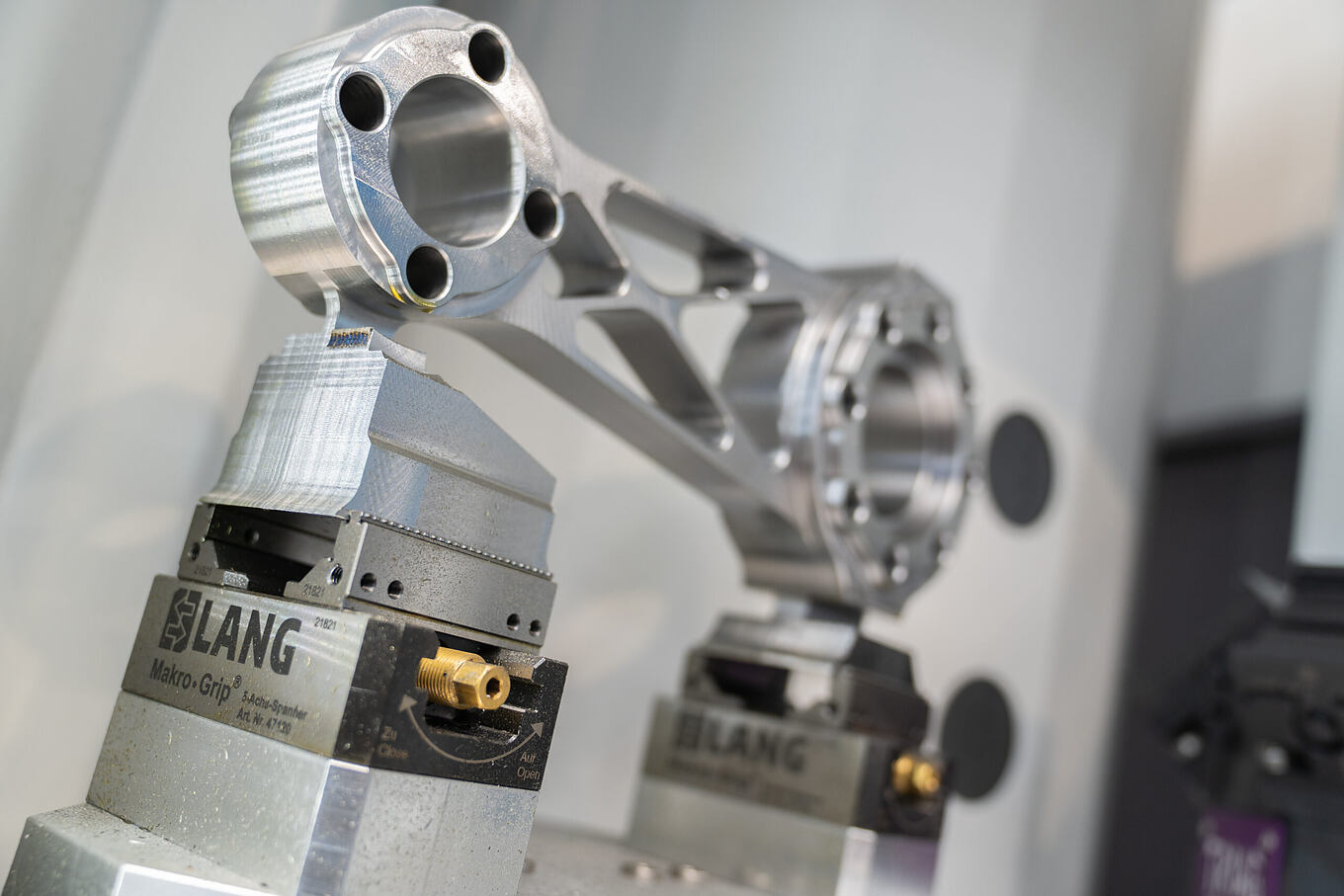

5-axis machining of a connecting rod utilizing an external CAM system

20.05.2021

Yamaha SR500 built on a HURCO

16.04.2021

Trochoidal milling – Standard with the WinMax-control

05.12.2019

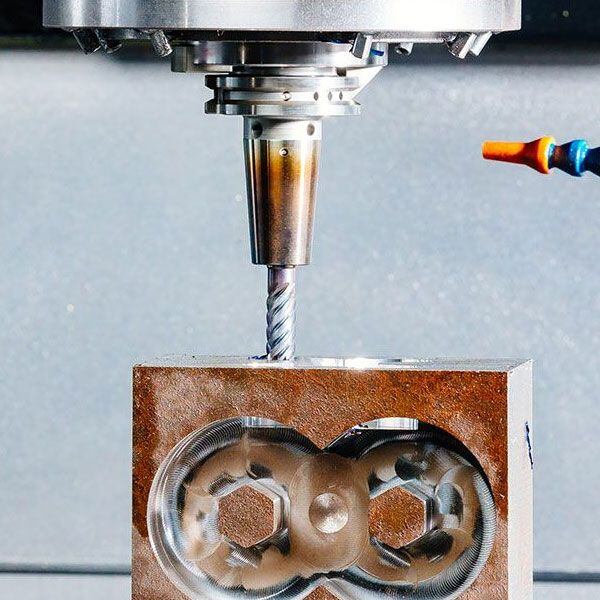

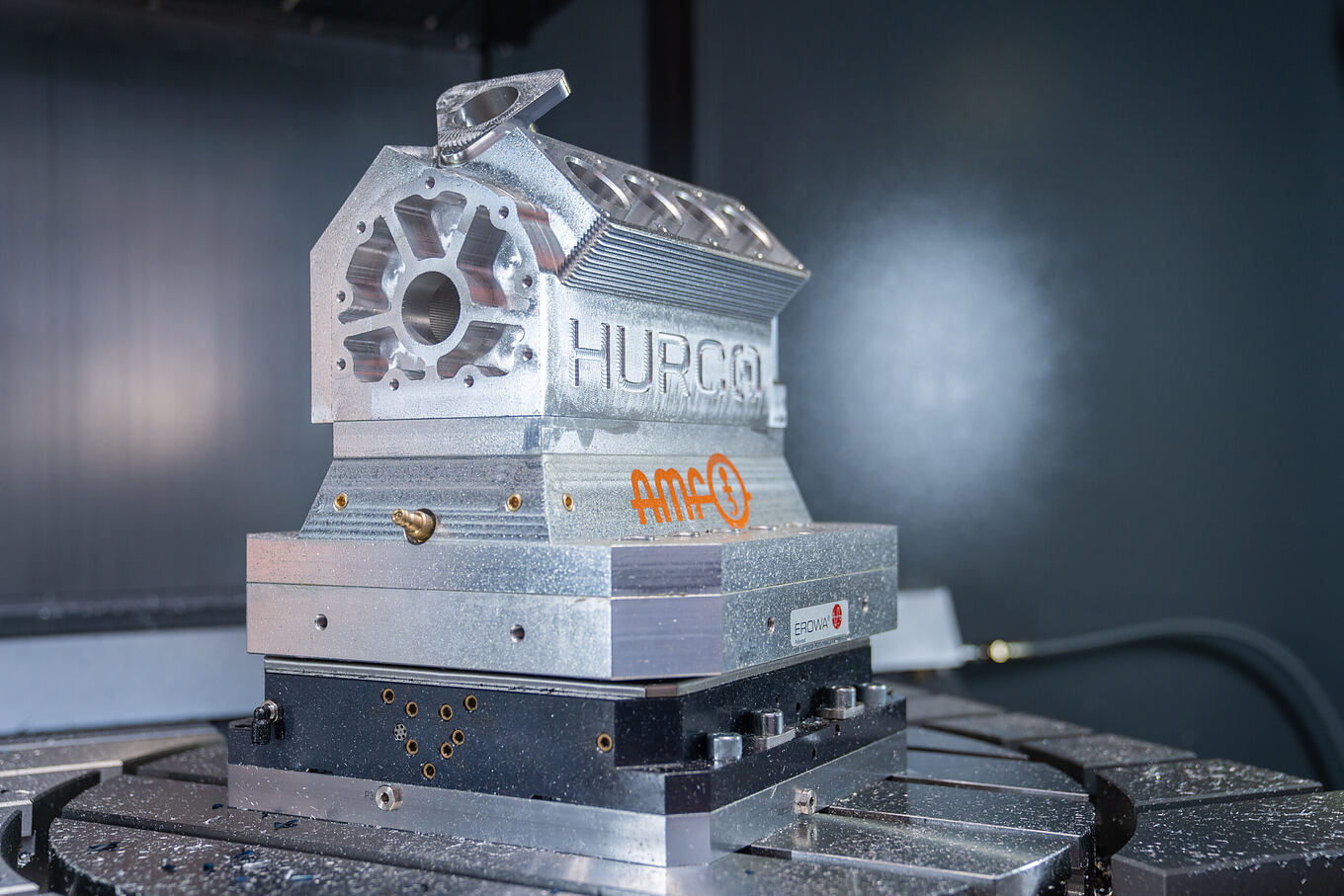

Aluminium engine block – CNC milling with a 5-axis machining center

16.10.2019

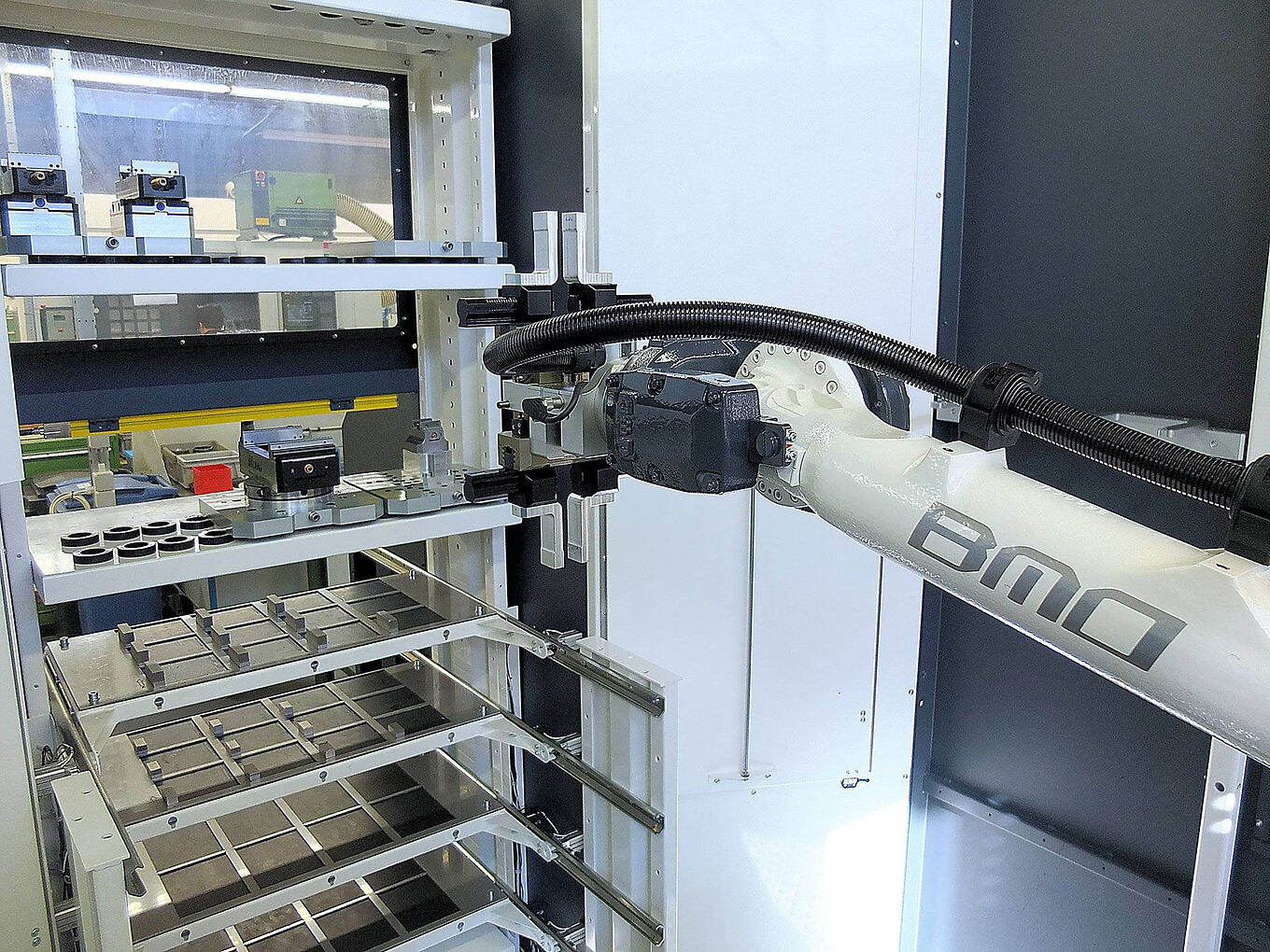

Machining centers – success factors for automation and industry 4.0

13.05.2019

The drivers of CNC 5-axis machining technology development – control and automation