- Products

- Control

- News & Media

- Company

- Kontakt

- Produktselektor

Automation with HURCO®: The ProCobots® Robotic Arm

Efficiency through automation

Automation in CNC machining aims to increase productivity, reduce loading times, minimize errors and downtime, and thereby improve overall efficiency. Automated loading processes with robotic arms allow personnel to be utilized more efficiently—for example, by preparing upcoming jobs while the current part is processed autonomously.

The ProCobots® Robotic Arm: Your Automation Advantage

- The HURCO® Automation Job Manager is fully integrated into the CNC control system of HURCO® machines. The robot is not programmed at the robot itself but via the intuitive HURCO® software directly at the machine control panel. This means your automated CNC lathe or milling machine with robotic arm is ready for production—smart and fast.

- The ProCobots® robotic solution is particularly attractive in times of skilled labor shortages.

- By using the robot, higher revenue can be generated with the same workforce.

- Thanks to extended machine run times, the ProCobots® ProFeeder can potentially generate up to €120,000 in additional revenue.*

Benefit from our ProCobots® automation system. We support you in automating your CNC machining center—quickly and efficiently.

*Based on machine hourly rate: €50

Machine operation: Mon–Fri 06:00–18:00, Sat 07:00–13:00

12 hours of downtime = approx. €600/day

5-day week = €3,000/week → €120,000/year

One Automation Solution—Many Possibilities

The ProCobots® robotic arm is compatible with a wide range of HURCO® machines—from compact 3-axis mills to powerful 5-axis machining centers and flexible CNC lathes. The result: greater efficiency across your entire production setup.

One investment - double the benefits

In addition to the annual revenue potential, you also benefit from an attractive introductory discount when automating your HURCO® machine with ProCobots®. Our sales experts will create a customized automation package to get you started with autonomous CNC manufacturing—cost-efficient and future-ready.

What Is Automation?

Automation means using digital processes and mechanical technologies to increase efficiency and productivity in machining.

Once the machining program is created via conversational input or G-code, including tool data and cutting parameters, even complex parts can be manufactured automatically.

With integrated hardware such as robotic arms, the material flow can be automated—loading raw parts and unloading finished components without manual intervention.

Why Automate?

Companies aiming for a competitive edge increasingly rely on automation solutions—especially with the ongoing shortage of skilled labor. Robotic modules such as CNC robotic arms can take over repetitive tasks, enhancing flexibility and productivity. Automating the loading of milling or turning machines enables high throughput with minimal manual effort.

HURCO® ProCobots® – High-Level Automation, Made Simple

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe Standard Package: Systematic Loading

HURCO®’s automation package is the ideal solution for boosting your CNC productivity.

The ProCobots® robotic arm enables automatic loading of your CNC machine.

Quickly switch between machines for flexible series production.

Most automation projects pay for themselves within a year.

Minimize Downtime, Maximize Profit

By reducing machine idle time, companies can unlock up to €120,000 in additional annual revenue.

This estimate is based on:

- €50/hour machine rate

- Avg. 11 hours/day runtime

- 6 working days/week

→ 24/7 milling and turning becomes reality.

Key Features at a Glance

- Automatic doors with manual override via handheld pendant

- Schunk gripper: for parts up to 15 kg (UR20 | UR30)

- Air nozzle for chip removal from fixtures and parts

- Cobot safety: protective disc and floor scanner ensure safe operation

Have questions? Use our contact form to get in touch with our automation specialists.

ProCobots® Loading Systems in Detail

The ProCobots® loading systems support your team in machining operations by handling the part loading automatically—freeing up staff for more complex, value-added tasks.

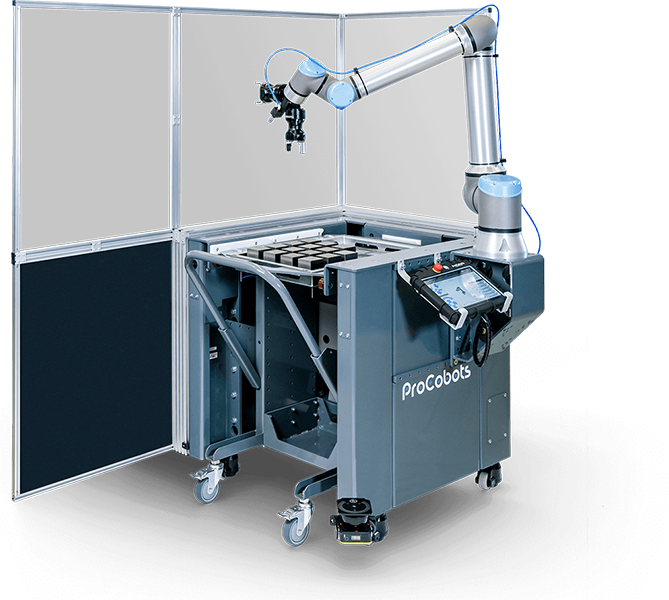

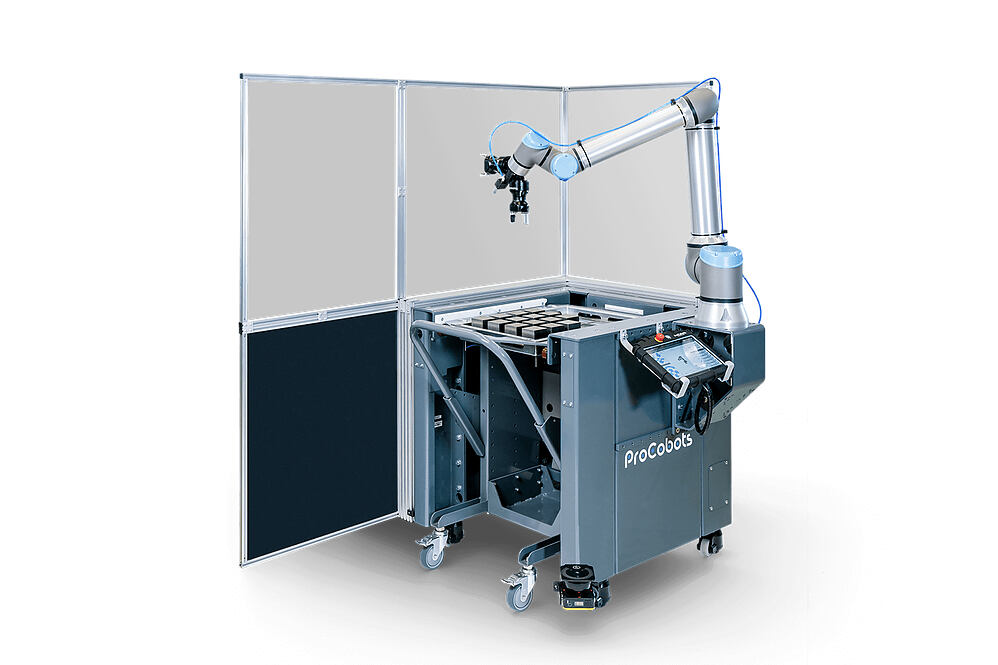

Robotic Arms

Universal Robots' robotic arms support loading of your machine tools:

- UR10e in ProFeeder Cart and Tray

- UR20 / UR30 in EasyDesk 20 | 30 systems

Your All-in-One Automation Package

Efficiency with automation

From hardware and software to installation and training, the HURCO® ProCobots® solution is a complete turnkey package.

- Hardware: ProFeeder Cart & Table with UR10e robotic arm

- Software: Automation Job Manager, fully integrated in MAX®5 control

- No need for programming at the robot itself

- Easy-to-use interface, short learning curve

- When you choose a ProCobots® system from HURCO®, you’re not only getting best-in-class equipment, but also comprehensive support from our experienced automation team—including installation and optional operator training.

We look forward to helping you get started!